Michiel Erasmus (9N)

Shannon Erasmus (9N)

Courtney Tink (9A)

Kayleigh McKee (9A)

Amour Nel (9A)

Ashlin Raath (9A)

Claudia Horn (9N)

Kerryn Herb (9W)

Mark Allocation

A) Individual research (5)

(Presented in class and posted to the blogsite)

B) Group presentation (Total of 20)

(Presented at seminar)

Presentation (5)

Content (5)

Delivery (5)

Research quality (5)

C) Group member peer assesment (5)

(Team leaders evaluate their members involvement)

Note* - Marks may be moderated if students appeal against non contributing members of their group.

(Presented in class and posted to the blogsite)

B) Group presentation (Total of 20)

(Presented at seminar)

Presentation (5)

Content (5)

Delivery (5)

Research quality (5)

C) Group member peer assesment (5)

(Team leaders evaluate their members involvement)

Note* - Marks may be moderated if students appeal against non contributing members of their group.

Design

1) Jane' Storm in (9R)

Extreme Loads -Forces:

Wind turbines are built to catch the wind's kinetic (motion) energy.

Turbines with many blades or very wide blades, will be subject to very large forces, when the wind blows at a hurricane speed.

Wind turbine manufacturers have to certify that their turbines are built, so that they can withstand extreme winds which occur, say, during 10 minutes once every 50 years.

To limit the influence of the extreme winds turbine manufacturers therefore generally prefer to build turbines with a few, long, narrow blades.

In order to make up for the narrowness of the blades facing the wind, turbine manufacturers prefer to let the turbines rotate relatively quickly.

Fatigue Loads -Forces:

This is particularly the case if they are located in a very turbulent wind climate.

Components which are subject to repeated bending, such as rotor blades, may eventually develop cracks which ultimately may make the component break. Metal fatigue is a well known problem in many industries. Metal is therefore generally not favoured as a material for rotor blades.

When designing a wind turbine it is extremely important to calculate in advance how the different components will vibrate, both individually, and jointly. It is also important to calculate the forces involved in each bending or stretching of a component.

This is the subject of structural dynamics, where physicists have developed mathematical computer models that analyse the behaviour of an entire wind turbine.

These models are used by wind turbine manufacturers to design their machines safely.

Upwind Machines:

Upwind machines have the rotor facing the wind. The basic advantage of upwind designs is that one avoids the wind shade behind the tower. By far the vast majority of wind turbines have this design.

The basic drawback of upwind designs is that the rotor needs to be made rather inflexible, and placed at some distance from the tower (as some manufacturers have found out to their cost). In addition an upwind machine needs a yaw mechanism to keep the rotor facing the wind.

Downwind Machines:

Downwind machines have the rotor placed on the lee side of the tower. They have the theoretical advantage that they may be built without a yaw mechanism, if the rotor and nacelle have a suitable design that makes the nacelle follow the wind passively. For large wind turbines this is a somewhat doubtful advantage, however, since you do need cables to lead the current away from the generator. How do you untwist the cables, when the machine has been yawing passively in the same direction for a long period of time, if you do not have a yaw mechanism? (Slip rings or mechanical collectors are not a very good idea if you are working with 1000 ampere currents).

A more important advantage is that the rotor may be made more flexible. This is an advantage both in regard to weight, and the structural dynamics of the machine. The basic advantage of the downwind machine is thus, that it may be built somewhat lighter than an upwind machine.

The basic drawback is the fluctuation in the wind power due to the rotor passing through the wind shade of the tower. This may give more fatigue loads on the turbine than with an upwind design.

Megan Hesse (9N)

Patricia edwards (9N)

Naudette McDuling (9R)

Danielle Botha (9A)

Saba Ashoori (9N)

Darryl - Lynne Borcher (9C)

Krisna Els (9A)

Gabby Farmer (9A)

Nkateko Phakula (9R)

Lisa Jeneker (9N)

Erashin Moodley (9W)

Carmen Fourie (9R)

Emica Swart (9W)

Claire Jordaan (9W)

Daleen Conradie (9R)

John Atfield (9N)

Rhys Rae (9A)

Extreme Loads -Forces:

Wind turbines are built to catch the wind's kinetic (motion) energy.

Turbines with many blades or very wide blades, will be subject to very large forces, when the wind blows at a hurricane speed.

Wind turbine manufacturers have to certify that their turbines are built, so that they can withstand extreme winds which occur, say, during 10 minutes once every 50 years.

To limit the influence of the extreme winds turbine manufacturers therefore generally prefer to build turbines with a few, long, narrow blades.

In order to make up for the narrowness of the blades facing the wind, turbine manufacturers prefer to let the turbines rotate relatively quickly.

Fatigue Loads -Forces:

This is particularly the case if they are located in a very turbulent wind climate.

Components which are subject to repeated bending, such as rotor blades, may eventually develop cracks which ultimately may make the component break. Metal fatigue is a well known problem in many industries. Metal is therefore generally not favoured as a material for rotor blades.

When designing a wind turbine it is extremely important to calculate in advance how the different components will vibrate, both individually, and jointly. It is also important to calculate the forces involved in each bending or stretching of a component.

This is the subject of structural dynamics, where physicists have developed mathematical computer models that analyse the behaviour of an entire wind turbine.

These models are used by wind turbine manufacturers to design their machines safely.

Upwind Machines:

Upwind machines have the rotor facing the wind. The basic advantage of upwind designs is that one avoids the wind shade behind the tower. By far the vast majority of wind turbines have this design.

The basic drawback of upwind designs is that the rotor needs to be made rather inflexible, and placed at some distance from the tower (as some manufacturers have found out to their cost). In addition an upwind machine needs a yaw mechanism to keep the rotor facing the wind.

Downwind Machines:

Downwind machines have the rotor placed on the lee side of the tower. They have the theoretical advantage that they may be built without a yaw mechanism, if the rotor and nacelle have a suitable design that makes the nacelle follow the wind passively. For large wind turbines this is a somewhat doubtful advantage, however, since you do need cables to lead the current away from the generator. How do you untwist the cables, when the machine has been yawing passively in the same direction for a long period of time, if you do not have a yaw mechanism? (Slip rings or mechanical collectors are not a very good idea if you are working with 1000 ampere currents).

A more important advantage is that the rotor may be made more flexible. This is an advantage both in regard to weight, and the structural dynamics of the machine. The basic advantage of the downwind machine is thus, that it may be built somewhat lighter than an upwind machine.

The basic drawback is the fluctuation in the wind power due to the rotor passing through the wind shade of the tower. This may give more fatigue loads on the turbine than with an upwind design.

Megan Hesse (9N)

Patricia edwards (9N)

Naudette McDuling (9R)

Danielle Botha (9A)

Saba Ashoori (9N)

Darryl - Lynne Borcher (9C)

Krisna Els (9A)

Gabby Farmer (9A)

Nkateko Phakula (9R)

Lisa Jeneker (9N)

Erashin Moodley (9W)

Carmen Fourie (9R)

Emica Swart (9W)

Claire Jordaan (9W)

Daleen Conradie (9R)

John Atfield (9N)

Rhys Rae (9A)

Legal

1) Henno Viljoen (9N)

Planning Requirements

(according to USA Bylaws)

* Utility notifications

* Temperary meterological tower

* Design standards

* Appearance approval by FAA

* Danger lighting for overflying planes

* Height restricted to 150m

* Bystanding emergency services

* Access controlled area

2) Estee van Niekerk (9C)

As-of-Right Siting:

As-of-Right Siting shall mean that development may proceed without the need for a special permit, variance, amendment, waiver, or other discretionary approval. As-of-right development may be subject to non-discretionary site plan review to determine conformance with local zoning bylaws as well as state and federal law. As-of-right development projects that are consistent with zoning bylaws and with state and federal law cannot be prohibited

Building Permit:

The permit issued in accordance with all applicable requirements of the Massachusetts State Building Code (780 CMR).

Designated Location: The location[s] designated by [the community’s local legislative body] in accordance with M.G.L. c. 40A, section 5, where wind energy facilities may be sited as-of right. Said location is shown on a Zoning Map. This map is hereby made a part of this Zoning Bylaw and is on file in the Office of the [Town/City] Clerk.

Height:

The height of a wind turbine measured from natural grade to the tip of the rotor blade at its highest point, or blade-tip height. The height of the wind energy facility will have a direct impact on the amount of power it generates. While actual outputs vary, a wind turbine that is 250 feet tall will have an average nameplate capacity of roughly 660 kW, whereas a turbine that is 450 feet will have an average nameplate capacity of roughly 1.5 to 2.0 MW. As previously mentioned, to satisfy the as-of-right zoning requirement contained in the Green Communities Act, the as-of-right bylaw must allow for the construction and operation of wind generation facilities that utilize at least one turbine with a rated nameplate capacity of 600 kW or more. Actual generating capacity must be considered not only in terms of tower height, but also in light of average wind speeds at a given location.

Precious Ngobeni (9R)

Karabo Mafolo (9N)

Marzele vd Merwe (9W)

Victoria blackbeard (9W)

Tundo Mjoli (9R)

Kholofelo Moshitisho (9R)

Kgomotso Matlawe (9O)

Samantha Taylor (9N)

Planning Requirements

(according to USA Bylaws)

* Utility notifications

* Temperary meterological tower

* Design standards

* Appearance approval by FAA

* Danger lighting for overflying planes

* Height restricted to 150m

* Bystanding emergency services

* Access controlled area

2) Estee van Niekerk (9C)

As-of-Right Siting:

As-of-Right Siting shall mean that development may proceed without the need for a special permit, variance, amendment, waiver, or other discretionary approval. As-of-right development may be subject to non-discretionary site plan review to determine conformance with local zoning bylaws as well as state and federal law. As-of-right development projects that are consistent with zoning bylaws and with state and federal law cannot be prohibited

Building Permit:

The permit issued in accordance with all applicable requirements of the Massachusetts State Building Code (780 CMR).

Designated Location: The location[s] designated by [the community’s local legislative body] in accordance with M.G.L. c. 40A, section 5, where wind energy facilities may be sited as-of right. Said location is shown on a Zoning Map. This map is hereby made a part of this Zoning Bylaw and is on file in the Office of the [Town/City] Clerk.

Height:

The height of a wind turbine measured from natural grade to the tip of the rotor blade at its highest point, or blade-tip height. The height of the wind energy facility will have a direct impact on the amount of power it generates. While actual outputs vary, a wind turbine that is 250 feet tall will have an average nameplate capacity of roughly 660 kW, whereas a turbine that is 450 feet will have an average nameplate capacity of roughly 1.5 to 2.0 MW. As previously mentioned, to satisfy the as-of-right zoning requirement contained in the Green Communities Act, the as-of-right bylaw must allow for the construction and operation of wind generation facilities that utilize at least one turbine with a rated nameplate capacity of 600 kW or more. Actual generating capacity must be considered not only in terms of tower height, but also in light of average wind speeds at a given location.

Precious Ngobeni (9R)

Karabo Mafolo (9N)

Marzele vd Merwe (9W)

Victoria blackbeard (9W)

Tundo Mjoli (9R)

Kholofelo Moshitisho (9R)

Kgomotso Matlawe (9O)

Samantha Taylor (9N)

Public relations and marketing

1) VB (9W)

Noise

Large turbine is noise similar to, but lower than a revving jet engine. motion of rotorblades and cogwheels can be minimised with a damping system. Property values could drop in radius of turbine.

2) JY (9W)

look & feel Special paint is required (heat, UV and rainproof) Plascon an option. WT vibration into ground could impact worm life.

Noise

Large turbine is noise similar to, but lower than a revving jet engine. motion of rotorblades and cogwheels can be minimised with a damping system. Property values could drop in radius of turbine.

2) JY (9W)

look & feel Special paint is required (heat, UV and rainproof) Plascon an option. WT vibration into ground could impact worm life.

Maintenance

1) Nicholas Leighton (90)

Supplies 100 jobs for the average WTpower plant.

WT less than conventional forms of conventional generation.

Usually twice per anum with about 12 - 18 hour downtime for each event.

1Megawatt plus WT's are coming out with maintenance warranties.

Modern WT's are designed to run for about 120 000 hours.

Maintenance cost increases as WT's age.

Danish WT's studies show cheaper maintenance in newer generation WT's.

Older WT's of 25kWh - 150kWh are about 3% of purchase price per anum.

Newer WT's are about 1.5 - 2%.

Most of cost is a fixed amount pa for regular services but a fixed amount of kWh is generally preferred $0.01per kWh (wear and tear increases with increasing production)

Rotor blades and gearbox is more suseptable to wear and tear.

Major ovehauls are possible, i.e. blades, gearbox, generator at about 15% - 20% of original replacement price of the WT.

Supplies 100 jobs for the average WTpower plant.

WT less than conventional forms of conventional generation.

Usually twice per anum with about 12 - 18 hour downtime for each event.

1Megawatt plus WT's are coming out with maintenance warranties.

Modern WT's are designed to run for about 120 000 hours.

Maintenance cost increases as WT's age.

Danish WT's studies show cheaper maintenance in newer generation WT's.

Older WT's of 25kWh - 150kWh are about 3% of purchase price per anum.

Newer WT's are about 1.5 - 2%.

Most of cost is a fixed amount pa for regular services but a fixed amount of kWh is generally preferred $0.01per kWh (wear and tear increases with increasing production)

Rotor blades and gearbox is more suseptable to wear and tear.

Major ovehauls are possible, i.e. blades, gearbox, generator at about 15% - 20% of original replacement price of the WT.

Placement

1) Martolis Pieters (9O)

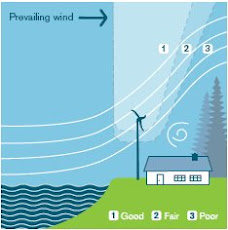

WT's Need a wide open, flat and obstacle free view (sweeping area) in the prevailing wind direction.

Windspeed is influenced by contours of local terrain.

Large WT's needs to connect to an electrical grid.Small WT's need to be close to a 10-30kilovolt powerline.

The powergrid may need to be reinforced if multiple Wt's are connected to it.

Soil conditions requires accessability of heavy machines as well as solid substrata.

2) Annette van der Merwe (90)

The common way is placement on hills or ridges overlloking the surrounding landscape facing the prevailing wind direction.

Hills have higher wind speeds because wind becomes compressed on the windward side of the hill when the air reaches the ridge it can expand again as it flows down into the low pressure area.

If the hill is steep or has an uneven surface turbulence is common which may negate the advantage of higher wind speeds.

3) YC - (90)

Noise 2 types of Noise: Aerodynamic sound (reduced by micro processor) Mechanical sound (battery charging capability reduces flutter) Sound increases with bade speed. Shape of blade determines the type of noise.

WT's Need a wide open, flat and obstacle free view (sweeping area) in the prevailing wind direction.

Windspeed is influenced by contours of local terrain.

Large WT's needs to connect to an electrical grid.Small WT's need to be close to a 10-30kilovolt powerline.

The powergrid may need to be reinforced if multiple Wt's are connected to it.

Soil conditions requires accessability of heavy machines as well as solid substrata.

2) Annette van der Merwe (90)

The common way is placement on hills or ridges overlloking the surrounding landscape facing the prevailing wind direction.

Hills have higher wind speeds because wind becomes compressed on the windward side of the hill when the air reaches the ridge it can expand again as it flows down into the low pressure area.

If the hill is steep or has an uneven surface turbulence is common which may negate the advantage of higher wind speeds.

3) YC - (90)

Noise 2 types of Noise: Aerodynamic sound (reduced by micro processor) Mechanical sound (battery charging capability reduces flutter) Sound increases with bade speed. Shape of blade determines the type of noise.

4) Gous Germishuys (9C)

Factors Influencing Placement:

-Wind availability

-Wind speed

-Turbulence

-Availability of transmission lines

-Energy produced

-Municipal Laws

-Cost of land acquisition

-Land use considerations

-Environmental impact of construction and operations.

-Soil type-Rocks under soil

What wind turbines require:

For a wind turbine to produce power and for that power to reach our school our wind turbine(s) need:

-To be close to a main power line

-Constant wind as well as winds with adequate wind speeds (depending on the turbine)

-To be at least 10m above any obstruction within a 100m radius of the turbine (including trees)

-As little turbulence as possible because turbulence puts strain on all the parts in a generator

-No objects blocking wind direction to the wind turbine

-Tower must have a “fall-zone” that does not impact any neighbouring property

-Large open spaces

Ideal wind turbine position:

If a wind turbine was to be built on the Cornwall Hill College property or in the Cornwall Hill Estate, there would be many problems because of the nearby military air-force base. Although if permission is granted, the wind turbine could be built at this possible location.

-The corner of the school --Geographical co-ordinates ----25°52’28.64”S 28°14’16.27”E

(See photos at the start of the section)

- Because there are no classrooms + buildings nearby to be affected by noise pollution, except when there is sport at those fields. It is the flattest area, with more than 100m radius.

-I have no information on the soil in that area nor information about power lines in that area.

Thshepiso Mabusela (9R)

Kamilla Snyman (9A)

Emilie Niewoudt (9O)

Chante De Klerk (9A)

Gavin Badenhorst (9C)

Jaimie Fouche (9C)

Jonathan Wocke (9N)

Herman de Klerk (9A)

Nico Till (9A)

Aiden Markram (9N)

Safety

1) Chane Ferreira (9O)

Components are designed to last app. 20 years. (120 000 operating hours)

Some large WT have safety features:

Vibration sensors:Ball on chain which falls off on over vibration and switches off the WT.

Overspeed protection:Stops the WT if any main component fails.

2) Nicole Milne (9A)

WT's has to work in all weather conditions.

Countries have varying regulations. i.e.

In Denmark rotorblades are tested by 5million revolutions (dynamic forces)

They are also tested against static forces.

WT's must be able to stop automatically incase they overheat or disconnect.

Independant Failsafe Breaking mechanism.

Different rules apply for High and low voltage WT's.

BWEA Specialized wind turbine training facility. (Common industry approach)

Operators need a WTSR qualification. (Wind Turbine Safety Rules)

3) Sarah Kew-Simpson (9W)

Any energy generation affects the environment.

Death of birds and bats a concern with environmental agencies which would look at migratory patterns in the EIA which would determine site location.

EIA (Environmental Impact Assesment) is compulsory before approval from NERSA.

WT affects the aesthetic value of the property.

Industrial equipment and moving blades are a harzard which needs to be made safe in terms of special conditions relating to a school environment.

4) Vincent Van Vuuren (9A)

Noise: Earlier models were noiser than modern ones.

Sound made by the blades are often masked by the wind.

Later are more efficient by converting more wind into torque.

Propeller noise can be reduced by different materials and settings.

5) Chante De Klerk (9A)

A robust system is required to survive lightning strikes.

6) Daniel Patrick (9R)

Negative affects on Fauna and Flora need to be assesed via EIA .

Main concerns are birds and plant species.

Conflicts could be resolved through agencies such as Greenpeace or WWF.

7) Teran Neveling (9R)

Noise pollution is one of the biggest disadvantages of a WT

Noise can extend for more than a mile.

There is very little noise directly under the WT

Modern technology increases the efficiency of the WT but it fails to decrease the noise output levels

8) Jaco Louw (90)

WT construction requires large foundations and can disrupt water flow above and below ground.

Industrial liquids used at the WT site can cause contamination.

WT's can cause debris scatter of flames and ice.

Fires can be caused by welding splatter during maintenance, electrical short circuits.

High fires is difficult to extinguish.

Sleep maladies such as nausea and headaches can occur due to what doctors call "Wind Turbine Syndromme"

9)Tamsin Tustin (9R)

The most noticeable impact of a wind turbine is noise pollution.

Modern technologies are increasing the efficiency of wind turbines, yet they fail to decrease the noise output by significant levels.

The noise pollution can greatly depend on the average annual wind speed (i.e. the higher the wind speed, the greater the noise output will be) and the size of the blades. Two types of noises are generated by a wind turbine: aerodynamic (from the blades) and mechanical (from the rotating machinery).

The site, careful design, insulating materials and operation should ensure that wind turbine noise is not a nuisance.

10) Amy Kirby (9W)

WT should have vibration sensors, if the WT starts shaking it automatically switches off.

WT should have electronics thermometers which checks the temperature of the oil in the gear box and the temperature of the generator

If the generator overheats or is disconnected from the electronical grid, the WT will start accelerating rapidly. Therefore we should have a over speed protection system

Aerodynamic braking system – primary braking system.

Mechanical braking system – back up for the Aerodynamic braking system and has a parking brake.

Conical tubular steel towers are preferred over a lattice tower because is safer and far more comfortable for the service to access the wind turbine fro repair and maintenance. The disadvantage – cost.

11) Isabel Muller (9C)

Nina Pierpont, a pediatrician based in New York, studied 10 families who lived close to wind farms, and says eight out of the 10 ended up moving away from their homes because of WTS-related illnesses. That’s a small survey sample, but it’s a continuation of research done by other scientists in the field. Pierpont recommends that wind turbines should be built at least 2 kilometers (a little over a mile) away from people’s homes, and she tells the Independent that: “It is irresponsible of the wind turbine companies — and governments — to continue building wind turbines so close to where people live until there has been a proper epidemiological investigation of the full impact on human health.”

The problem, according to Pierpont, is that the wind farms emit a constant low-frequency vibration and noise, which human beings are sensitive to (not unlike fish’s sensitivity to noise in the water) and the wind farm vibrations can disrupt the inner ear’s vestibular system (responsible for balance and spatial orientation). Over a sustained period of time, people living too close to the wind farms can develop a disorder related to the inner ear disruption, WTS (wind turbine syndrome), which can cause nervousness, heart disorders, nightmares, problems and even cognitive development issues in small children.

Symptoms

Three doctors have been studying the Wind Turbine Syndrome: one in the US, one in England, and one in Australia. They note the same sets of symptoms. The symptoms start when local turbines go into operation and resolve when the turbines are off or when the person is out of the area. The symptoms include:

1) Sleep problems: noise or physical sensations of pulsation or pressure make it hard to go to sleep and cause frequent awakening.

2) Headaches which are increased in frequency or severity.

3) Dizziness, unsteadiness, and nausea.

4) Exhaustion, anxiety, anger, irritability, and depression.

5) Problems with concentration and learning.

6) Tinnitus (ringing in the ears).

Not everyone near turbines has these symptoms. This does not mean people are making them up; it means there are differences among people in susceptibility. These differences are known as risk factors. Defining risk factors and the proportion of people who get symptoms is the role of epidemiologic studies. These studies are under way. Chronic sleep disturbance is the most common symptom. Exhaustion, mood problems, and problems with concentration and learning are natural outcomes of poor sleep.

12) VB (9W)

Large turbine is noise similar to, but lower than a revving jet engine. motion of rotorblades and cogwheels can be minimised with a damping system. Property values could drop in radius of turbine.

Components are designed to last app. 20 years. (120 000 operating hours)

Some large WT have safety features:

Vibration sensors:Ball on chain which falls off on over vibration and switches off the WT.

Overspeed protection:Stops the WT if any main component fails.

2) Nicole Milne (9A)

WT's has to work in all weather conditions.

Countries have varying regulations. i.e.

In Denmark rotorblades are tested by 5million revolutions (dynamic forces)

They are also tested against static forces.

WT's must be able to stop automatically incase they overheat or disconnect.

Independant Failsafe Breaking mechanism.

Different rules apply for High and low voltage WT's.

BWEA Specialized wind turbine training facility. (Common industry approach)

Operators need a WTSR qualification. (Wind Turbine Safety Rules)

3) Sarah Kew-Simpson (9W)

Any energy generation affects the environment.

Death of birds and bats a concern with environmental agencies which would look at migratory patterns in the EIA which would determine site location.

EIA (Environmental Impact Assesment) is compulsory before approval from NERSA.

WT affects the aesthetic value of the property.

Industrial equipment and moving blades are a harzard which needs to be made safe in terms of special conditions relating to a school environment.

4) Vincent Van Vuuren (9A)

Noise: Earlier models were noiser than modern ones.

Sound made by the blades are often masked by the wind.

Later are more efficient by converting more wind into torque.

Propeller noise can be reduced by different materials and settings.

5) Chante De Klerk (9A)

A robust system is required to survive lightning strikes.

6) Daniel Patrick (9R)

Negative affects on Fauna and Flora need to be assesed via EIA .

Main concerns are birds and plant species.

Conflicts could be resolved through agencies such as Greenpeace or WWF.

7) Teran Neveling (9R)

Noise pollution is one of the biggest disadvantages of a WT

Noise can extend for more than a mile.

There is very little noise directly under the WT

Modern technology increases the efficiency of the WT but it fails to decrease the noise output levels

8) Jaco Louw (90)

WT construction requires large foundations and can disrupt water flow above and below ground.

Industrial liquids used at the WT site can cause contamination.

WT's can cause debris scatter of flames and ice.

Fires can be caused by welding splatter during maintenance, electrical short circuits.

High fires is difficult to extinguish.

Sleep maladies such as nausea and headaches can occur due to what doctors call "Wind Turbine Syndromme"

9)Tamsin Tustin (9R)

The most noticeable impact of a wind turbine is noise pollution.

Modern technologies are increasing the efficiency of wind turbines, yet they fail to decrease the noise output by significant levels.

The noise pollution can greatly depend on the average annual wind speed (i.e. the higher the wind speed, the greater the noise output will be) and the size of the blades. Two types of noises are generated by a wind turbine: aerodynamic (from the blades) and mechanical (from the rotating machinery).

The site, careful design, insulating materials and operation should ensure that wind turbine noise is not a nuisance.

10) Amy Kirby (9W)

WT should have vibration sensors, if the WT starts shaking it automatically switches off.

WT should have electronics thermometers which checks the temperature of the oil in the gear box and the temperature of the generator

If the generator overheats or is disconnected from the electronical grid, the WT will start accelerating rapidly. Therefore we should have a over speed protection system

Aerodynamic braking system – primary braking system.

Mechanical braking system – back up for the Aerodynamic braking system and has a parking brake.

Conical tubular steel towers are preferred over a lattice tower because is safer and far more comfortable for the service to access the wind turbine fro repair and maintenance. The disadvantage – cost.

11) Isabel Muller (9C)

Nina Pierpont, a pediatrician based in New York, studied 10 families who lived close to wind farms, and says eight out of the 10 ended up moving away from their homes because of WTS-related illnesses. That’s a small survey sample, but it’s a continuation of research done by other scientists in the field. Pierpont recommends that wind turbines should be built at least 2 kilometers (a little over a mile) away from people’s homes, and she tells the Independent that: “It is irresponsible of the wind turbine companies — and governments — to continue building wind turbines so close to where people live until there has been a proper epidemiological investigation of the full impact on human health.”

The problem, according to Pierpont, is that the wind farms emit a constant low-frequency vibration and noise, which human beings are sensitive to (not unlike fish’s sensitivity to noise in the water) and the wind farm vibrations can disrupt the inner ear’s vestibular system (responsible for balance and spatial orientation). Over a sustained period of time, people living too close to the wind farms can develop a disorder related to the inner ear disruption, WTS (wind turbine syndrome), which can cause nervousness, heart disorders, nightmares, problems and even cognitive development issues in small children.

Symptoms

Three doctors have been studying the Wind Turbine Syndrome: one in the US, one in England, and one in Australia. They note the same sets of symptoms. The symptoms start when local turbines go into operation and resolve when the turbines are off or when the person is out of the area. The symptoms include:

1) Sleep problems: noise or physical sensations of pulsation or pressure make it hard to go to sleep and cause frequent awakening.

2) Headaches which are increased in frequency or severity.

3) Dizziness, unsteadiness, and nausea.

4) Exhaustion, anxiety, anger, irritability, and depression.

5) Problems with concentration and learning.

6) Tinnitus (ringing in the ears).

Not everyone near turbines has these symptoms. This does not mean people are making them up; it means there are differences among people in susceptibility. These differences are known as risk factors. Defining risk factors and the proportion of people who get symptoms is the role of epidemiologic studies. These studies are under way. Chronic sleep disturbance is the most common symptom. Exhaustion, mood problems, and problems with concentration and learning are natural outcomes of poor sleep.

12) VB (9W)

Large turbine is noise similar to, but lower than a revving jet engine. motion of rotorblades and cogwheels can be minimised with a damping system. Property values could drop in radius of turbine.

Specifications

1) Andrew Walters (90)

Horisontal WT

- Small WT's have wind vanes that turns the blade towards the wind.

- Large WT's has a gearbox that turns the blade towards the wind.

- Every 10m of height increases the wind by app. 20% and output capacity by 34%

- Hard to transport

- Difficult to install and maintain.

- Can interfere with cellular towers.

Vertical WT

- Do not need to pointed into the wind.

- Good for places where wind direction changes a lot.

- Easier to maintain because of access to gearbox and blades proximity to the ground.

- Smaller and lighter (Can be placed on buildings)

- Can start producing power at 10km/h

- Less efficient in high winds compared to horisontal WT's

2) Phillip Rust (90)

Some WT could have blades that are 35m or longer and stand as high as 65m.

Required wind speed for a tower WT is app. 25mph.

Operational sweeping footprint of a 1.5megawatt WT's blade is app. 3 square kilometres.

Volkswind (Germany):150watt capacity

Westas and General Electric (American):1.5 - 3 megawatt capacity, total height app. 100m

3) Alexander Ham (9A)

Early windmills in Holland just had flat blades compared to the modern aerofoil that creats lift which pulls the blade along.

In "lift" one of the blade is flat and the opposite side is curved. when the wind moves over the curved area it speeds up and creates a low pressure pocket above the blade. The low pressure area "pulls" the blade towards it.

The is a limit the speed that a WT blade can travel called the "Betz limit" ( Named after the person who discovered and formulated the eqasion) Blades create a high pressure area in front whilst rotating which forces some air out and around the WT.

4) Marjolein Naudé (9A)

Wind turbines are designed to exploit the wind energy that exists at a location. Aerodynamic modeling is used to determine the optimum tower height, control systems, number of blades {factApril 2009} and blade shape. Wind turbines convert wind energy to electricity for distribution.

Conventional horizontal axis turbines can be divided into three components.

The rotor component, which is approximately 20% of the wind turbine cost, includes the blades for converting wind energy to low speed rotational energy.

The generator component, which is approximately 34% of the wind turbine cost, includes the electrical generator, the control electronics, and most likely a gearbox component for converting the low speed incoming rotation to high speed rotation suitable for generating electricity.

The structural support component, which is approximately 15% of the wind turbine cost, includes the tower and rotor yaw mechanism."

5) Nicholas Herbst (9C)

This is an example of WT specifications supplied by a company called African Windpower. www.africanwindpower.com

These should help give guidelines to many aspects of the project. Keeping in mind this is a very small WT so a multiple of these might be needed in order to cover the CHC electrical bill.

AWP 3.7 Specifications

Peak Power Rating

1500 W at 48V - 2000 W in 110/220V Inverter Grid Connect System

Energy Production

(Predicted) 4m/s 8KWHrs/Day, 5m/s 12KWHrs/Day,6m/s 20KWHrs/Day

Rated Wind Speed

12m/s

Start up wind Speed

3.5m/sec

Cut in Wind Speed

3m/sec

Alternator Design

30 Pole (Ceramic Magnet) Rotor, Laminated Axial Stator

Electrical Output

3 Phase 'Wild' AC, 0-100Hz, 12V,24V,36V,48V,96V,110/220V

Rotor Diameter

3.7 Meters

Maximum RPM

500

Number of Blades

3

Blade Construction

GRP Composite design

Speed/Power Control

Side Furling Gravity Return Yaw System

Max Design Windspeed

60m/sec

Configuration

Upwind Rotor - furling tail

Corrosion protection

Powder coated (White)

Marine protection

Hot dip galvanised

Cable Connection

Heavy duty slip rings

Tower Top Mounting

3 Inch (80mm NB) Table D Flange - (4 x 18mm Bolts 150mm PCD)

Tower Top Weight

120Kgs (220 Pounds)

Battery Charge Control

Turbine Side ,high side diversion dump control

Dump Load

Wall mounted resistive heater 1500W

Shipping dimensions

160Kg (308 Pound) Crate 1900x 570x 540mm (74x23x21ins)

6) Stas Osuch '9C'

Specifications for an 80 k/w wind turbine:

Ideal use for:

• Schools/office buildings

• Poultry/cattle/dairy farms

• Resort hotels

• Golf courses

• Agricultural businesses

• Manufacturing plants

• Remote villages - island power systems

The noise produced is 95 decibels at a speed of 10 m\s. This at the source, right next to the turbine. 100m away from the turbine there are 45 decibels produced. That means that about 200 meters away from the turbine it will not be heard. It has Sound reduced gearbox, rotor blades with minimized noise level.

Dimensions:

Rotor – 18m diameter carbon fiber (9 meter each blade).

Tower - 18-40m. made out of steel: tubular or lattice.

Foundation – Concrete block with anchors.

‘a-synchronous generator.’ Produces 160,000 kWhrs yearly.

Weight 13 000 kg.

Safety features:

Electro mechanical pitch control for each blade.

Hydrolic parking brake.

Cost: $120,000 (R 965,387.993)

The lightning protection system :

Lightning receptors installed on blade tips.

Surge protection in electrical components.

This comes pre-engineered.

Liam O Niel (90)

Tim Marshall (9C)

Andrew Van Zyl (9W)

Connor Davison (9O)

Blaine Witten (9N)

Lauren Teichert (9N)

Kgomotso Mogashoa (9O)

Erryn Moodley (9N)

Roger dos Santos (9R)

Riccardo Rincon (9R)

Bradley Cohoe (9W)

Nicholas Leighten (9O)

Victor Wymeersch (9C)

Ryan Phillips (9W)

Damian Lewis (9C)

Aidan Taylor (9A)

Karl Frenzel (9W)

Gregory Avieros (9W)

Dylan Hull (9R)

Ruben Pretorius (9W)

Kaylan Naicker (9C)

Horisontal WT

- Small WT's have wind vanes that turns the blade towards the wind.

- Large WT's has a gearbox that turns the blade towards the wind.

- Every 10m of height increases the wind by app. 20% and output capacity by 34%

- Hard to transport

- Difficult to install and maintain.

- Can interfere with cellular towers.

Vertical WT

- Do not need to pointed into the wind.

- Good for places where wind direction changes a lot.

- Easier to maintain because of access to gearbox and blades proximity to the ground.

- Smaller and lighter (Can be placed on buildings)

- Can start producing power at 10km/h

- Less efficient in high winds compared to horisontal WT's

2) Phillip Rust (90)

Some WT could have blades that are 35m or longer and stand as high as 65m.

Required wind speed for a tower WT is app. 25mph.

Operational sweeping footprint of a 1.5megawatt WT's blade is app. 3 square kilometres.

Volkswind (Germany):150watt capacity

Westas and General Electric (American):1.5 - 3 megawatt capacity, total height app. 100m

3) Alexander Ham (9A)

Early windmills in Holland just had flat blades compared to the modern aerofoil that creats lift which pulls the blade along.

In "lift" one of the blade is flat and the opposite side is curved. when the wind moves over the curved area it speeds up and creates a low pressure pocket above the blade. The low pressure area "pulls" the blade towards it.

The is a limit the speed that a WT blade can travel called the "Betz limit" ( Named after the person who discovered and formulated the eqasion) Blades create a high pressure area in front whilst rotating which forces some air out and around the WT.

4) Marjolein Naudé (9A)

Wind turbines are designed to exploit the wind energy that exists at a location. Aerodynamic modeling is used to determine the optimum tower height, control systems, number of blades {factApril 2009} and blade shape. Wind turbines convert wind energy to electricity for distribution.

Conventional horizontal axis turbines can be divided into three components.

The rotor component, which is approximately 20% of the wind turbine cost, includes the blades for converting wind energy to low speed rotational energy.

The generator component, which is approximately 34% of the wind turbine cost, includes the electrical generator, the control electronics, and most likely a gearbox component for converting the low speed incoming rotation to high speed rotation suitable for generating electricity.

The structural support component, which is approximately 15% of the wind turbine cost, includes the tower and rotor yaw mechanism."

5) Nicholas Herbst (9C)

This is an example of WT specifications supplied by a company called African Windpower. www.africanwindpower.com

These should help give guidelines to many aspects of the project. Keeping in mind this is a very small WT so a multiple of these might be needed in order to cover the CHC electrical bill.

AWP 3.7 Specifications

Peak Power Rating

1500 W at 48V - 2000 W in 110/220V Inverter Grid Connect System

Energy Production

(Predicted) 4m/s 8KWHrs/Day, 5m/s 12KWHrs/Day,6m/s 20KWHrs/Day

Rated Wind Speed

12m/s

Start up wind Speed

3.5m/sec

Cut in Wind Speed

3m/sec

Alternator Design

30 Pole (Ceramic Magnet) Rotor, Laminated Axial Stator

Electrical Output

3 Phase 'Wild' AC, 0-100Hz, 12V,24V,36V,48V,96V,110/220V

Rotor Diameter

3.7 Meters

Maximum RPM

500

Number of Blades

3

Blade Construction

GRP Composite design

Speed/Power Control

Side Furling Gravity Return Yaw System

Max Design Windspeed

60m/sec

Configuration

Upwind Rotor - furling tail

Corrosion protection

Powder coated (White)

Marine protection

Hot dip galvanised

Cable Connection

Heavy duty slip rings

Tower Top Mounting

3 Inch (80mm NB) Table D Flange - (4 x 18mm Bolts 150mm PCD)

Tower Top Weight

120Kgs (220 Pounds)

Battery Charge Control

Turbine Side ,high side diversion dump control

Dump Load

Wall mounted resistive heater 1500W

Shipping dimensions

160Kg (308 Pound) Crate 1900x 570x 540mm (74x23x21ins)

6) Stas Osuch '9C'

Specifications for an 80 k/w wind turbine:

Ideal use for:

• Schools/office buildings

• Poultry/cattle/dairy farms

• Resort hotels

• Golf courses

• Agricultural businesses

• Manufacturing plants

• Remote villages - island power systems

The noise produced is 95 decibels at a speed of 10 m\s. This at the source, right next to the turbine. 100m away from the turbine there are 45 decibels produced. That means that about 200 meters away from the turbine it will not be heard. It has Sound reduced gearbox, rotor blades with minimized noise level.

Dimensions:

Rotor – 18m diameter carbon fiber (9 meter each blade).

Tower - 18-40m. made out of steel: tubular or lattice.

Foundation – Concrete block with anchors.

‘a-synchronous generator.’ Produces 160,000 kWhrs yearly.

Weight 13 000 kg.

Safety features:

Electro mechanical pitch control for each blade.

Hydrolic parking brake.

Cost: $120,000 (R 965,387.993)

The lightning protection system :

Lightning receptors installed on blade tips.

Surge protection in electrical components.

This comes pre-engineered.

Liam O Niel (90)

Tim Marshall (9C)

Andrew Van Zyl (9W)

Connor Davison (9O)

Blaine Witten (9N)

Lauren Teichert (9N)

Kgomotso Mogashoa (9O)

Erryn Moodley (9N)

Roger dos Santos (9R)

Riccardo Rincon (9R)

Bradley Cohoe (9W)

Nicholas Leighten (9O)

Victor Wymeersch (9C)

Ryan Phillips (9W)

Damian Lewis (9C)

Aidan Taylor (9A)

Karl Frenzel (9W)

Gregory Avieros (9W)

Dylan Hull (9R)

Ruben Pretorius (9W)

Kaylan Naicker (9C)

Cost

1) Michael Yang (9A)

CHC school uses approximately 100Kw monthly and that our electricity bills are app. R 45 000.00 monthly.

The price of wind turbines in order to cover this monthly energy requirement of CHC can vary from 2M to 3M depending on whether you want many turbines or just one and the quality of the turbine/s. There is a constant maintenance cost of about R25 000 - R30 000 every year ( which includes 5 inspection per year).

Blades need to be replaced app. every ten years at app. R10 000 - R50 000 per blade

(However by then may be better to install a new wind turbine).

It is estimated that money if the wind turbines work properly and cover all electricity amounts, that CHC will be able to cover the cost they paid for the wind turbines in 5 - 8 years.

Research regarding which specific models that are cost-efficient and suit CHC is ongoing.

The model currently in favour is the WES mk1 80 kW model which costs approximately 2.5M

Relevance is to reduce the CHC carbon footprint / electrical bill.

A projected KW/h of double the current usage would be prudent to cover growth of energy use fot the next 20years.

2) Tsela Simpiwe (90)

Focus on Kestrel WT's.(RSA)1.2M - 2.6M rand for commericial WT's (installed excluding licensing)

3) Karl Frenzel (9W)

Current purchase price is determined by the economy and exchange rate.

Commercial size WT 1.2M - 2.6M per megawatt (installed)

Average power delivery per commercial turbine is app. 2megawatt.

Residential size WT is cheaper to install but more expensive per kilowatt.Average household needs app. 10Kilowatt per month which would cost app. R350 000

4) Anusha Lakha (9A)

A deep cycle battery costs app. R604 500

Operation and maintenance costs increases with the time that the WT is operational.

Payback could be as much as 10 years and WT life expectance could be as much as to 25 years.

Gearbox and rotorblade repair are the major maintenace factors which could be 15-20% of the WT purchase price.

5) Naudette McDulling (9R)

Bank feasibility study to determine loans and interest repayable.

A reasonably detailed outline would be submitted to some banks.

6) Megan Smith (90)

(Purchase prices of WT's excluding spare parts and operating materials)

200kW - 300 kW

app. R16 000 - R31 000

500kW

app. R40 000 - R48 000

1500hW

app. R80 000 - 1.2M

1 extra metre of tower about R11 900

The company Engineered wind systems recommends the following options for schools:

WES 250kW Turbine

multiples of 50kW Turbine

Re-driven 20kW Turbine

7) Marco Nkosi (9c)

Sponsorship. The company Adventure power wind turbine manufacturers supplies wt and they also supply sponsorship for projects that want to go green, and guess what this project is about going green. You can visit their site at http://www.gnsummit.co.za/ . Another well known company except kestrel that supplies good wt is urban green energy.Kestrel number: 041 401 2500

8) KF (9W)

Current purchase price is determined by the economy and exchange rate.

Commercial size WT 1.2M - 2.6M per megawatt (installed)

Average power delivery per commercial turbine is app. 2megawatt.

Residential size WT is cheaper to install but more expensive per kilowatt.

Average household needs app. 10Kilowatt per month which would cost app. R350 000

Two types available horisontal and vertical axle.

Horisontal Axle WT:

- blades on the side(more stable)

- pitch of blades can be changed (efficient wind harvesting)

- rotorblade speed can be controlled

- causes turbulence near ground

- shipping and transport cost is a factor

- requires skilled installation

Vertical Axle WT:

- easy to maintain

- does not require tower (lowers cost)

- overcomes height restriction bylaws

- only produce half of horisontal axle WT output

- has a low starting torque rate

- needs flat land to be installed

9) Kristin Mc Jarrow (9N)

Interestingly enough the price increase when looking at larger wind turbines is more cost effective. If you go from 150 kW to 600 kW the price does not quadruple, but instead it triples. This is because it is not much more difficult to make a larger wind turbine then it is to make a smaller one, simply more material is involved, the physics and mechanics is the same.

The insurance costs are about 35% of the total costs of the wind turbine per year.

Permit Fees:

Permitting requirements, procedures, and fees vary widely among counties. Fees for building permits, usage permits, zoning permits, and plot plans can range from R1000 to R5000. There may be other fees for public notification, hearings, and environmental impact studies costing from a few hundred to several thousand dollars. Remember, if a fee seems inappropriate or excessive, you may be able to get it reduced. Find out what you are being charged for and offer to provide documentation or information that makes the fee unnecessary.

A carbon tax is a tax on energy sources which emit carbon dioxide into the atmosphere. The purpose of a carbon tax is environmental, to reduce emissions of carbon dioxide and thereby slow global warming. It can be implemented by taxing the burning of fossil fuels — coal, petroleum products such as gasoline and aviation fuel, and natural gas — in proportion to their carbon content. About 11 cents/kWh is charged on the burning of these fuels. By using wind energy these costs are taken away completely and therefore you are able to save even more! Many people save money on electricity by using wind power.

*The South African government is planning to implement this soon.

10) The Economics of Wind Energy

The economics of wind energy have changed dramatically over the past twenty years, as the cost of wind power has fallen approximately 90 percent during that period. Despite that progress, the wind industry is still somewhat immature, with production volumes that pale in comparison to what they will be two decades from now. Thus, the factors affecting the cost of wind energy are still rapidly changing, and wind energy’s costs will continue to decline as the industry grows and matures.

A number of factors determine the economics of utility-scale wind energy and its competitiveness in the energy marketplace.

The cost of wind energy varies widely depending upon the wind speed at a given project site. The energy that can be tapped from the wind is proportional to the cube of the wind speed, so a slight increase in wind speed results in a large increase in electricity generation. Consider two sites, one with an average wind speed of 14 miles per hour (mph) and the other with average winds of 16 mph. All other things being equal, a wind turbine at the second site will generate nearly 50% more electricity than it would at the first location.

Cost of energy and Wind

The three examples above are for costs per kilowatt-hour for a 51 MW wind farm at three different average wind speeds expressed in meters per second. Cost figures include the current wind production tax credit.

Improvements in turbine design bring down costs. The taller the turbine tower and the larger the area swept by the blades, the more powerful and productive the turbine. The swept area of a turbine rotor (a circle) is a function of the square of the blade length (the circle’s radius).

Therefore, a fivefold increase in rotor diameter (from 10 meters on a 25-kW turbine like those built in the 1980s to 50 meters on a 750-kW turbine common today) yields a 55-fold increase in yearly electricity output, partly because the swept area is 25 times larger and partly because the tower height has increased substantially, and wind speeds increase with distance from the ground.

Advances in electronic monitoring and controls, blade design, and other features have also contributed to a drop in cost. The following table shows how a modern 1.65-MW turbine generates 120 times the electricity at one-sixth the cost of an older 25-kW turbine:

1981 2000

A large wind farm is more economical than a small one. Assuming the same average wind speed of 18 mph and identical wind turbine sizes, a 3–MW wind project delivers electricity at a cost of $0.059 per kWh and a 51-MW project delivers electricity at $0.036 per kWh—a drop in costs of $0.023, or nearly 40%. Any project has transaction costs that can be spread over more kilowatt-hours with a larger project. Similarly, a larger project has lower O&M (operations and maintenance) costs per kilowatt-hour because of the efficiencies of managing a larger wind farm.

Cost figures include the current wind production tax credit.

Optimal configuration of the turbines to take the best advantage of micro-features on the terrain will also improve a project's productivity. i

The cost of financing affects the cost of wind energy. Wind energy is capital-intensive, so the cost of financing constitutes a large variable in a wind energy project's economics. For a variety of reasons, financing for wind projects remains more expensive than for mainstream forms of electricity generation.

Project ownership affects cost of financing and the economics of a wind power project. Independent ownership—that is, financing of projects by private power producers on a stand-alone basis, which is how the vast majority of U.S. wind projects are financed—is more expensive than utility-owned financing. According to a study by Lawrence Berkeley National Laboratory, ii utility ownership of a wind facility results in a significantly lower estimated levelized cost of energy, because lower-cost financing available to large electric utilities (IOUs, or investor-owned utilities) is not available for non-IOU wind projects. IOU ownership reduces levelized costs by approximately 30%, the study found.

In addition, although wind turbine technology has steadily progressed to a point where its reliability is today comparable to that of other energy technologies, it is still regarded as "novel" and "risky" by many members of the U.S. financial community (most U.S. projects are still financed by European-based lenders). Lenders therefore offer less favourable financing terms and demand a higher return on investment than for more “conventional” energy sources.

Table: The economics of a 50-MW wind farm at a wind site with average wind speed of 13-17 mph (class 4). Figures are indicative only.

Project size: 50 MW

Capital cost: $65 million ($1.3 million per MW)

Annual power production

(assuming 35% capacity factor) 150 million kWh

Financing: 60% debt, 40% equity

Annual gross revenue: $6 million (assuming power purchase price

of 4 cents per kWh)

Expenses:

-Debt: 60% (15 years at 9.5%)

-Distribution 22%

-Operation and maintenance (8%)

-Land, property taxes, or rent 5%

-Mgt fees, insurance 5%

Tax credit and depreciation: -5-year depreciation on wind equipment

-1.5 c/kWh credit adjusted for inflation during first ten years of operation

The Lawrence Berkeley Laboratory study found that a 50-MW wind farm delivering power at just under 5 cents per kWh would, if using typical natural gas project financing terms, generate electricity for 3.69 cents per kWh.

Transmission, tax, environmental, and other policies also affect the economics of wind.

Transmission and market access constraints can significantly affect the cost of wind energy. Since wind speeds vary, wind plant operators cannot perfectly predict the amount of electricity they will be delivering to transmission lines in a given hour. Deviations from schedule are often penalized without regard to whether they increase or decrease system costs. Interconnection procedures are not standardized, and utilities have on occasion imposed such difficult and burdensome requirement on wind plants for connection to transmission lines that wind companies have chosen to build their own lines instead.

As electricity markets are restructured and long-term power purchase agreements give way to trading on power exchanges, transmission and market access conditions will play an increasingly important role in the economics of a wind project.

The federal tax code, which provides a variety of permanent and temporary incentives for conventional forms of energy, also includes a production tax credit (PTC) for wind energy and a 5-year accelerated depreciation schedule for wind turbines. The 1.5 cent-per-kWh PTC is adjusted for inflation (currently it stands at 1.8 cents/kWh) and supports electricity generated from utility-scale wind turbines for the first ten years of their operation. The PTC, first adopted in 1992, was extended in 1999, again, through 2003 after its expiration in 2001, and most recently through December 31, 2005 after its expiration in 2004. In order to qualify for the credit, generators must now complete installations and start production before the 2005 expiration date. The PTC may be reduced or cancelled if a project applies for state incentives such as a grant or no-interest loan, under federal "anti-double-dipping" rules. Iii

The PTC, a key incentive, helps level the economic playing field for wind projects in energy markets where other forms of energy are also subsidized. It must be noted, however, that the current “on-again, off-again” status of the credit is hobbling project development and the industry as a whole. Uncertainty also affects relationships with vendors and substantially increases costs as orders are rushed to meet PTC deadlines or as planning grinds to a halt and income is lost while the industry awaits an extension. One major U.S. developer stated that a five-year extension of the PTC would provide enough long-term certainty to squeeze an additional 25 percent out of vendor costs. The wind energy industry is currently seeking a long-term extension of the credit.

Stricter environmental regulations enhance wind energy’s competitiveness. Wind power’s environmental impact per unit of electricity generated is much lower than that of mainstream forms of electricity generation, as wind energy neither emits pollutants, wastes, or greenhouse gases, nor damages the environment through resource extraction.

The higher the air quality and other environmental standards adopted in a country, the more competitive wind energy therefore becomes in the marketplace. Conversely, a relaxation of standards or failure to internalize environmental costs through pollution charges or other processes makes polluting forms of electricity generation appear deceptively cheap.This is an important economic issue, because the hidden "subsidy" that governments and markets give to polluting energy sources by partially or fully ignoring their health and environmental costs is typically much larger than direct subsidies to such energy sources.

Wind energy provides ancillary economic benefits:

• less dependence on fossil fuels, which can be subject to rapid price fluctuations and supply problems (by the end of 2006, AWEA estimates wind energy use will save over 0.5 billion cubic feet (Bcf) of natural gas each day, relieving some of the current supply shortages);

• steady income for farmers or ranchers who own the land on which windfarms are built, and for the communities in which they live (in Texas, for example, ranchers have been reaping income from the wind even as their royalties from oil wells have declined);

• An increase in the property tax base for rural counties.

i "Economics of Wind Farm Layout," Alan Germain and Donald Bain, Windpower 1997 proceedings (American Wind Energy Association, Washington, D.C.).

ii "Alternative Windpower Ownership Structures: Financing Terms and Project Costs," Ryan Wiser and Edward Kahn, Lawrence Berkeley Laboratory, Energy and Environment Division, 1996.

iii "Anti-Double Dipping Rules for Federal Tax Incentives, Edwin Ing, Windpower 1997 proceedings.

iv The cost of producing electricity from coal or oil would double and the cost of electricity production from gas would increase by 30% if some external costs such as damage to the environment (not including that of global warming) and to health were taken into account, according to a study by the European Union Similarly, in the U.S., state attempts to set up a process by which some of the environmental costs of electricity production, or externalities, could be taken into account in economic calculations have focused on air emissions and set externalities estimates in the range of 3-6 cents per kWh for coal and 0.5 to 2 cents per kWh for natural gas. For a comprehensive study see Ottinger et al., “Environmental Costs of Electricity,” Pace University Center for Environmental Legal Studies, Oceana Publications, 1990.

Wind turbines can be found to have many shapes and sizes. The cost of it can be indicated clearly as per the following paragraphs. The cost depends upon the project size, purchase agreement construction contracts, type of machines, and the projects location as well as other related factors.

How much does a wind turbine cost can be answered partially. Cost components for wind turbines which are distinct from commercial scale wind turbine as outlined above. The cost includes wind resource assessment, site analysis expenses, the freight of the turbine and its price, as well as tower, construction expenses, interconnection studies, utility system upgrades, protection, transformers, as well as metering equipment, operations, warranty, maintenance, repair, insurance, legal and consultation fees, etc.

Other factors which have an impact on your project economics are financing costs, the size of the project and applicability of taxes.

How much does a wind turbine cost can be answered as under:

The cost of the commercial wind turbines varied from $1 to $2 million per MW of nameplate capacity installed. The same turbines 2 MW in size cost roughly $2.8 million installed capacity. These turbines undergo significant economies scale. Smaller farm or residential scale turbines cost less but they are more expensive when per kilowatt of energy producing capacity is applied on the rates.

This would indicate a 10 kilowatt machine might cost roughly around $48,000. In this manner 100 kilowatts wind turbines would cost roughly $2,800 to $4,800 per kilowatt of capacity. To conclude, how much does a wind turbine cost can be summarized by proper negotiation, considering engineering and other related factors and reducing over all cost incidence on the production process.

Many people save money on electricity by using wind power. Power your house with wind energy and build your own wind turbine with less than 200$. Best guide reviewed.

Best guide to start using wind power as energy and make your own wind powered turbine.

How do residential wind turbines work?

A wind turbine, which is installed on top of a tall tower, collects kinetic energy from the wind and converts it to electricity that is compatible with a home's electrical system.

In a normal residential application, a home is served simultaneously by the wind turbine and a local utility. If the wind speeds are below cut-in speed (7-10 mph) there will be no output from the turbine and all of the needed power is purchased from the utility. As wind speeds increase, turbine output increases and the amount of power purchased from the utility is proportionately decreased. When the turbine produces more power than the house needs, the extra electricity is sold to the utility. All of this is done automatically. There are no batteries in a modern residential wind system.

Small wind systems for remote applications operate somewhat differently.

Do wind turbines make noise or interfere with TV reception?

Small wind turbines do make some noise, but not enough to be found objectionable by most people. A typical residential wind system makes less noise than the average washing machine. Wind turbines do not interfere with TV reception.

Will my utility allow me to hook up a wind generator?

Federal regulations (specifically, the Public Utility Regulatory Policies Act of 1978, or PURPA) require utilities to connect with and purchase power from small (less than 80 MW) wind energy systems. A wind turbine manufacturer should be able to help arrange the required utility company approvals.

Will I have to change any of the wiring in my house?

No. A wind turbine is easily retrofitted to virtually any home without the need to change any wiring or appliances. In most cases, the utility will install a second utility meter to measure how much surplus electricity it is purchasing from the turbine owner.

What about towers?

An 80- to 120-foot tower is usually supplied along with the wind turbine. Towers this tall are necessary to raise the wind turbine above turbulence generated by obstacles on the ground and trees. Wind velocity and, therefore wind turbine performance, increases with altitude. Several different types of towers are available, depending upon which manufacturer you select. Each type has its advantages; the most economical type of tower is the guyed lattice tower, but a hinged tower can be easier for you to install yourself and provides easier access for maintenance.

How much does a wind system cost?

A small turbine can cost anywhere from $6,000 to $22,000 installed, depending upon size, application and service agreements with the manufacturer.

How reliable are wind turbines? Will I have to perform much maintenance?

Most small turbines have very few moving parts and do not require any regular maintenance. They are designed for a long life (up to 20 years) and operate completely automatically.

How do wind turbines perform as an investment?

The wind system will usually recoup its investment through utility savings within six to 15 years and after that the electricity it produces will be virtually free. Over the long term, a wind turbine is a good investment because a well-sited wind system increases property value, similar to any other home improvement. Many people buy wind systems in preparation for their retirement because they don't want to be subject to unpredictable increases in utility rates.

How would I have a wind turbine installed at my home?

Most dealers offer either complete turnkey (ready-to-operate) installations or the option to purchase direct from the factory and install the system yourself. The first option offers more customer support from the company. Self-installation offers significant savings and a hands-on understanding of the turbine. Prospective owners can discuss the options available with manufacturers to decide which method best suits their budget and technical skills.

Yietta Chrysostomou (9O)

Simphiwe Tsela (9O)

Amilcar Thobejane (9N)

Angelica Marques (9C)

Anuska Lakha (9A)

Sarah Dold (9N)

Giverny Ganz (9N)

Marc Relou (9R)

Amy Nickelson (9W)

Michael Boltman (9C)

Joshua Yeatman (9W)

Tyler Sanster (9W)

Michael Purnell (9N)

Blake Stead (9N)

Kirsten Trankle (9N)

CHC school uses approximately 100Kw monthly and that our electricity bills are app. R 45 000.00 monthly.

The price of wind turbines in order to cover this monthly energy requirement of CHC can vary from 2M to 3M depending on whether you want many turbines or just one and the quality of the turbine/s. There is a constant maintenance cost of about R25 000 - R30 000 every year ( which includes 5 inspection per year).

Blades need to be replaced app. every ten years at app. R10 000 - R50 000 per blade

(However by then may be better to install a new wind turbine).

It is estimated that money if the wind turbines work properly and cover all electricity amounts, that CHC will be able to cover the cost they paid for the wind turbines in 5 - 8 years.

Research regarding which specific models that are cost-efficient and suit CHC is ongoing.

The model currently in favour is the WES mk1 80 kW model which costs approximately 2.5M

Relevance is to reduce the CHC carbon footprint / electrical bill.

A projected KW/h of double the current usage would be prudent to cover growth of energy use fot the next 20years.

2) Tsela Simpiwe (90)

Focus on Kestrel WT's.(RSA)1.2M - 2.6M rand for commericial WT's (installed excluding licensing)

3) Karl Frenzel (9W)

Current purchase price is determined by the economy and exchange rate.

Commercial size WT 1.2M - 2.6M per megawatt (installed)

Average power delivery per commercial turbine is app. 2megawatt.

Residential size WT is cheaper to install but more expensive per kilowatt.Average household needs app. 10Kilowatt per month which would cost app. R350 000

4) Anusha Lakha (9A)

A deep cycle battery costs app. R604 500

Operation and maintenance costs increases with the time that the WT is operational.

Payback could be as much as 10 years and WT life expectance could be as much as to 25 years.

Gearbox and rotorblade repair are the major maintenace factors which could be 15-20% of the WT purchase price.

5) Naudette McDulling (9R)

Bank feasibility study to determine loans and interest repayable.

A reasonably detailed outline would be submitted to some banks.

6) Megan Smith (90)

(Purchase prices of WT's excluding spare parts and operating materials)

200kW - 300 kW

app. R16 000 - R31 000

500kW

app. R40 000 - R48 000

1500hW

app. R80 000 - 1.2M

1 extra metre of tower about R11 900

The company Engineered wind systems recommends the following options for schools:

WES 250kW Turbine

multiples of 50kW Turbine

Re-driven 20kW Turbine

7) Marco Nkosi (9c)

Sponsorship. The company Adventure power wind turbine manufacturers supplies wt and they also supply sponsorship for projects that want to go green, and guess what this project is about going green. You can visit their site at http://www.gnsummit.co.za/ . Another well known company except kestrel that supplies good wt is urban green energy.Kestrel number: 041 401 2500

8) KF (9W)

Current purchase price is determined by the economy and exchange rate.

Commercial size WT 1.2M - 2.6M per megawatt (installed)

Average power delivery per commercial turbine is app. 2megawatt.

Residential size WT is cheaper to install but more expensive per kilowatt.

Average household needs app. 10Kilowatt per month which would cost app. R350 000

Two types available horisontal and vertical axle.

Horisontal Axle WT:

- blades on the side(more stable)

- pitch of blades can be changed (efficient wind harvesting)

- rotorblade speed can be controlled

- causes turbulence near ground

- shipping and transport cost is a factor

- requires skilled installation

Vertical Axle WT:

- easy to maintain

- does not require tower (lowers cost)

- overcomes height restriction bylaws

- only produce half of horisontal axle WT output

- has a low starting torque rate

- needs flat land to be installed

9) Kristin Mc Jarrow (9N)

Interestingly enough the price increase when looking at larger wind turbines is more cost effective. If you go from 150 kW to 600 kW the price does not quadruple, but instead it triples. This is because it is not much more difficult to make a larger wind turbine then it is to make a smaller one, simply more material is involved, the physics and mechanics is the same.

The insurance costs are about 35% of the total costs of the wind turbine per year.

Permit Fees:

Permitting requirements, procedures, and fees vary widely among counties. Fees for building permits, usage permits, zoning permits, and plot plans can range from R1000 to R5000. There may be other fees for public notification, hearings, and environmental impact studies costing from a few hundred to several thousand dollars. Remember, if a fee seems inappropriate or excessive, you may be able to get it reduced. Find out what you are being charged for and offer to provide documentation or information that makes the fee unnecessary.

A carbon tax is a tax on energy sources which emit carbon dioxide into the atmosphere. The purpose of a carbon tax is environmental, to reduce emissions of carbon dioxide and thereby slow global warming. It can be implemented by taxing the burning of fossil fuels — coal, petroleum products such as gasoline and aviation fuel, and natural gas — in proportion to their carbon content. About 11 cents/kWh is charged on the burning of these fuels. By using wind energy these costs are taken away completely and therefore you are able to save even more! Many people save money on electricity by using wind power.

*The South African government is planning to implement this soon.

10) The Economics of Wind Energy

The economics of wind energy have changed dramatically over the past twenty years, as the cost of wind power has fallen approximately 90 percent during that period. Despite that progress, the wind industry is still somewhat immature, with production volumes that pale in comparison to what they will be two decades from now. Thus, the factors affecting the cost of wind energy are still rapidly changing, and wind energy’s costs will continue to decline as the industry grows and matures.

A number of factors determine the economics of utility-scale wind energy and its competitiveness in the energy marketplace.

The cost of wind energy varies widely depending upon the wind speed at a given project site. The energy that can be tapped from the wind is proportional to the cube of the wind speed, so a slight increase in wind speed results in a large increase in electricity generation. Consider two sites, one with an average wind speed of 14 miles per hour (mph) and the other with average winds of 16 mph. All other things being equal, a wind turbine at the second site will generate nearly 50% more electricity than it would at the first location.

Cost of energy and Wind

The three examples above are for costs per kilowatt-hour for a 51 MW wind farm at three different average wind speeds expressed in meters per second. Cost figures include the current wind production tax credit.

Improvements in turbine design bring down costs. The taller the turbine tower and the larger the area swept by the blades, the more powerful and productive the turbine. The swept area of a turbine rotor (a circle) is a function of the square of the blade length (the circle’s radius).

Therefore, a fivefold increase in rotor diameter (from 10 meters on a 25-kW turbine like those built in the 1980s to 50 meters on a 750-kW turbine common today) yields a 55-fold increase in yearly electricity output, partly because the swept area is 25 times larger and partly because the tower height has increased substantially, and wind speeds increase with distance from the ground.

Advances in electronic monitoring and controls, blade design, and other features have also contributed to a drop in cost. The following table shows how a modern 1.65-MW turbine generates 120 times the electricity at one-sixth the cost of an older 25-kW turbine:

1981 2000

A large wind farm is more economical than a small one. Assuming the same average wind speed of 18 mph and identical wind turbine sizes, a 3–MW wind project delivers electricity at a cost of $0.059 per kWh and a 51-MW project delivers electricity at $0.036 per kWh—a drop in costs of $0.023, or nearly 40%. Any project has transaction costs that can be spread over more kilowatt-hours with a larger project. Similarly, a larger project has lower O&M (operations and maintenance) costs per kilowatt-hour because of the efficiencies of managing a larger wind farm.