1) Michael Yang (9A)

CHC school uses approximately 100Kw monthly and that our electricity bills are app. R 45 000.00 monthly.

The price of wind turbines in order to cover this monthly energy requirement of CHC can vary from 2M to 3M depending on whether you want many turbines or just one and the quality of the turbine/s. There is a constant maintenance cost of about R25 000 - R30 000 every year ( which includes 5 inspection per year).

Blades need to be replaced app. every ten years at app. R10 000 - R50 000 per blade

(However by then may be better to install a new wind turbine).

It is estimated that money if the wind turbines work properly and cover all electricity amounts, that CHC will be able to cover the cost they paid for the wind turbines in 5 - 8 years.

Research regarding which specific models that are cost-efficient and suit CHC is ongoing.

The model currently in favour is the WES mk1 80 kW model which costs approximately 2.5M

Relevance is to reduce the CHC carbon footprint / electrical bill.

A projected KW/h of double the current usage would be prudent to cover growth of energy use fot the next 20years.

2) Tsela Simpiwe (90)

Focus on Kestrel WT's.(RSA)1.2M - 2.6M rand for commericial WT's (installed excluding licensing)

3) Karl Frenzel (9W)

Current purchase price is determined by the economy and exchange rate.

Commercial size WT 1.2M - 2.6M per megawatt (installed)

Average power delivery per commercial turbine is app. 2megawatt.

Residential size WT is cheaper to install but more expensive per kilowatt.Average household needs app. 10Kilowatt per month which would cost app. R350 000

4) Anusha Lakha (9A)

A deep cycle battery costs app. R604 500

Operation and maintenance costs increases with the time that the WT is operational.

Payback could be as much as 10 years and WT life expectance could be as much as to 25 years.

Gearbox and rotorblade repair are the major maintenace factors which could be 15-20% of the WT purchase price.

5) Naudette McDulling (9R)

Bank feasibility study to determine loans and interest repayable.

A reasonably detailed outline would be submitted to some banks.

6) Megan Smith (90)

(Purchase prices of WT's excluding spare parts and operating materials)

200kW - 300 kW

app. R16 000 - R31 000

500kW

app. R40 000 - R48 000

1500hW

app. R80 000 - 1.2M

1 extra metre of tower about R11 900

The company Engineered wind systems recommends the following options for schools:

WES 250kW Turbine

multiples of 50kW Turbine

Re-driven 20kW Turbine

7) Marco Nkosi (9c)

Sponsorship. The company Adventure power wind turbine manufacturers supplies wt and they also supply sponsorship for projects that want to go green, and guess what this project is about going green. You can visit their site at http://www.gnsummit.co.za/ . Another well known company except kestrel that supplies good wt is urban green energy.Kestrel number: 041 401 2500

8) KF (9W)

Current purchase price is determined by the economy and exchange rate.

Commercial size WT 1.2M - 2.6M per megawatt (installed)

Average power delivery per commercial turbine is app. 2megawatt.

Residential size WT is cheaper to install but more expensive per kilowatt.

Average household needs app. 10Kilowatt per month which would cost app. R350 000

Two types available horisontal and vertical axle.

Horisontal Axle WT:

- blades on the side(more stable)

- pitch of blades can be changed (efficient wind harvesting)

- rotorblade speed can be controlled

- causes turbulence near ground

- shipping and transport cost is a factor

- requires skilled installation

Vertical Axle WT:

- easy to maintain

- does not require tower (lowers cost)

- overcomes height restriction bylaws

- only produce half of horisontal axle WT output

- has a low starting torque rate

- needs flat land to be installed

9) Kristin Mc Jarrow (9N)

Interestingly enough the price increase when looking at larger wind turbines is more cost effective. If you go from 150 kW to 600 kW the price does not quadruple, but instead it triples. This is because it is not much more difficult to make a larger wind turbine then it is to make a smaller one, simply more material is involved, the physics and mechanics is the same.

The insurance costs are about 35% of the total costs of the wind turbine per year.

Permit Fees:

Permitting requirements, procedures, and fees vary widely among counties. Fees for building permits, usage permits, zoning permits, and plot plans can range from R1000 to R5000. There may be other fees for public notification, hearings, and environmental impact studies costing from a few hundred to several thousand dollars. Remember, if a fee seems inappropriate or excessive, you may be able to get it reduced. Find out what you are being charged for and offer to provide documentation or information that makes the fee unnecessary.

A carbon tax is a tax on energy sources which emit carbon dioxide into the atmosphere. The purpose of a carbon tax is environmental, to reduce emissions of carbon dioxide and thereby slow global warming. It can be implemented by taxing the burning of fossil fuels — coal, petroleum products such as gasoline and aviation fuel, and natural gas — in proportion to their carbon content. About 11 cents/kWh is charged on the burning of these fuels. By using wind energy these costs are taken away completely and therefore you are able to save even more! Many people save money on electricity by using wind power.

*The South African government is planning to implement this soon.

10) The Economics of Wind Energy

The economics of wind energy have changed dramatically over the past twenty years, as the cost of wind power has fallen approximately 90 percent during that period. Despite that progress, the wind industry is still somewhat immature, with production volumes that pale in comparison to what they will be two decades from now. Thus, the factors affecting the cost of wind energy are still rapidly changing, and wind energy’s costs will continue to decline as the industry grows and matures.

A number of factors determine the economics of utility-scale wind energy and its competitiveness in the energy marketplace.

The cost of wind energy varies widely depending upon the wind speed at a given project site. The energy that can be tapped from the wind is proportional to the cube of the wind speed, so a slight increase in wind speed results in a large increase in electricity generation. Consider two sites, one with an average wind speed of 14 miles per hour (mph) and the other with average winds of 16 mph. All other things being equal, a wind turbine at the second site will generate nearly 50% more electricity than it would at the first location.

Cost of energy and Wind

The three examples above are for costs per kilowatt-hour for a 51 MW wind farm at three different average wind speeds expressed in meters per second. Cost figures include the current wind production tax credit.

Improvements in turbine design bring down costs. The taller the turbine tower and the larger the area swept by the blades, the more powerful and productive the turbine. The swept area of a turbine rotor (a circle) is a function of the square of the blade length (the circle’s radius).

Therefore, a fivefold increase in rotor diameter (from 10 meters on a 25-kW turbine like those built in the 1980s to 50 meters on a 750-kW turbine common today) yields a 55-fold increase in yearly electricity output, partly because the swept area is 25 times larger and partly because the tower height has increased substantially, and wind speeds increase with distance from the ground.

Advances in electronic monitoring and controls, blade design, and other features have also contributed to a drop in cost. The following table shows how a modern 1.65-MW turbine generates 120 times the electricity at one-sixth the cost of an older 25-kW turbine:

1981 2000

A large wind farm is more economical than a small one. Assuming the same average wind speed of 18 mph and identical wind turbine sizes, a 3–MW wind project delivers electricity at a cost of $0.059 per kWh and a 51-MW project delivers electricity at $0.036 per kWh—a drop in costs of $0.023, or nearly 40%. Any project has transaction costs that can be spread over more kilowatt-hours with a larger project. Similarly, a larger project has lower O&M (operations and maintenance) costs per kilowatt-hour because of the efficiencies of managing a larger wind farm.

Cost figures include the current wind production tax credit.

Optimal configuration of the turbines to take the best advantage of micro-features on the terrain will also improve a project's productivity. i

The cost of financing affects the cost of wind energy. Wind energy is capital-intensive, so the cost of financing constitutes a large variable in a wind energy project's economics. For a variety of reasons, financing for wind projects remains more expensive than for mainstream forms of electricity generation.

Project ownership affects cost of financing and the economics of a wind power project. Independent ownership—that is, financing of projects by private power producers on a stand-alone basis, which is how the vast majority of U.S. wind projects are financed—is more expensive than utility-owned financing. According to a study by Lawrence Berkeley National Laboratory, ii utility ownership of a wind facility results in a significantly lower estimated levelized cost of energy, because lower-cost financing available to large electric utilities (IOUs, or investor-owned utilities) is not available for non-IOU wind projects. IOU ownership reduces levelized costs by approximately 30%, the study found.

In addition, although wind turbine technology has steadily progressed to a point where its reliability is today comparable to that of other energy technologies, it is still regarded as "novel" and "risky" by many members of the U.S. financial community (most U.S. projects are still financed by European-based lenders). Lenders therefore offer less favourable financing terms and demand a higher return on investment than for more “conventional” energy sources.

Table: The economics of a 50-MW wind farm at a wind site with average wind speed of 13-17 mph (class 4). Figures are indicative only.

Project size: 50 MW

Capital cost: $65 million ($1.3 million per MW)

Annual power production

(assuming 35% capacity factor) 150 million kWh

Financing: 60% debt, 40% equity

Annual gross revenue: $6 million (assuming power purchase price

of 4 cents per kWh)

Expenses:

-Debt: 60% (15 years at 9.5%)

-Distribution 22%

-Operation and maintenance (8%)

-Land, property taxes, or rent 5%

-Mgt fees, insurance 5%

Tax credit and depreciation: -5-year depreciation on wind equipment

-1.5 c/kWh credit adjusted for inflation during first ten years of operation

The Lawrence Berkeley Laboratory study found that a 50-MW wind farm delivering power at just under 5 cents per kWh would, if using typical natural gas project financing terms, generate electricity for 3.69 cents per kWh.

Transmission, tax, environmental, and other policies also affect the economics of wind.

Transmission and market access constraints can significantly affect the cost of wind energy. Since wind speeds vary, wind plant operators cannot perfectly predict the amount of electricity they will be delivering to transmission lines in a given hour. Deviations from schedule are often penalized without regard to whether they increase or decrease system costs. Interconnection procedures are not standardized, and utilities have on occasion imposed such difficult and burdensome requirement on wind plants for connection to transmission lines that wind companies have chosen to build their own lines instead.

As electricity markets are restructured and long-term power purchase agreements give way to trading on power exchanges, transmission and market access conditions will play an increasingly important role in the economics of a wind project.

The federal tax code, which provides a variety of permanent and temporary incentives for conventional forms of energy, also includes a production tax credit (PTC) for wind energy and a 5-year accelerated depreciation schedule for wind turbines. The 1.5 cent-per-kWh PTC is adjusted for inflation (currently it stands at 1.8 cents/kWh) and supports electricity generated from utility-scale wind turbines for the first ten years of their operation. The PTC, first adopted in 1992, was extended in 1999, again, through 2003 after its expiration in 2001, and most recently through December 31, 2005 after its expiration in 2004. In order to qualify for the credit, generators must now complete installations and start production before the 2005 expiration date. The PTC may be reduced or cancelled if a project applies for state incentives such as a grant or no-interest loan, under federal "anti-double-dipping" rules. Iii

The PTC, a key incentive, helps level the economic playing field for wind projects in energy markets where other forms of energy are also subsidized. It must be noted, however, that the current “on-again, off-again” status of the credit is hobbling project development and the industry as a whole. Uncertainty also affects relationships with vendors and substantially increases costs as orders are rushed to meet PTC deadlines or as planning grinds to a halt and income is lost while the industry awaits an extension. One major U.S. developer stated that a five-year extension of the PTC would provide enough long-term certainty to squeeze an additional 25 percent out of vendor costs. The wind energy industry is currently seeking a long-term extension of the credit.

Stricter environmental regulations enhance wind energy’s competitiveness. Wind power’s environmental impact per unit of electricity generated is much lower than that of mainstream forms of electricity generation, as wind energy neither emits pollutants, wastes, or greenhouse gases, nor damages the environment through resource extraction.

The higher the air quality and other environmental standards adopted in a country, the more competitive wind energy therefore becomes in the marketplace. Conversely, a relaxation of standards or failure to internalize environmental costs through pollution charges or other processes makes polluting forms of electricity generation appear deceptively cheap.This is an important economic issue, because the hidden "subsidy" that governments and markets give to polluting energy sources by partially or fully ignoring their health and environmental costs is typically much larger than direct subsidies to such energy sources.

Wind energy provides ancillary economic benefits:

• less dependence on fossil fuels, which can be subject to rapid price fluctuations and supply problems (by the end of 2006, AWEA estimates wind energy use will save over 0.5 billion cubic feet (Bcf) of natural gas each day, relieving some of the current supply shortages);

• steady income for farmers or ranchers who own the land on which windfarms are built, and for the communities in which they live (in Texas, for example, ranchers have been reaping income from the wind even as their royalties from oil wells have declined);

• An increase in the property tax base for rural counties.

i "Economics of Wind Farm Layout," Alan Germain and Donald Bain, Windpower 1997 proceedings (American Wind Energy Association, Washington, D.C.).

ii "Alternative Windpower Ownership Structures: Financing Terms and Project Costs," Ryan Wiser and Edward Kahn, Lawrence Berkeley Laboratory, Energy and Environment Division, 1996.

iii "Anti-Double Dipping Rules for Federal Tax Incentives, Edwin Ing, Windpower 1997 proceedings.

iv The cost of producing electricity from coal or oil would double and the cost of electricity production from gas would increase by 30% if some external costs such as damage to the environment (not including that of global warming) and to health were taken into account, according to a study by the European Union Similarly, in the U.S., state attempts to set up a process by which some of the environmental costs of electricity production, or externalities, could be taken into account in economic calculations have focused on air emissions and set externalities estimates in the range of 3-6 cents per kWh for coal and 0.5 to 2 cents per kWh for natural gas. For a comprehensive study see Ottinger et al., “Environmental Costs of Electricity,” Pace University Center for Environmental Legal Studies, Oceana Publications, 1990.

Wind turbines can be found to have many shapes and sizes. The cost of it can be indicated clearly as per the following paragraphs. The cost depends upon the project size, purchase agreement construction contracts, type of machines, and the projects location as well as other related factors.

How much does a wind turbine cost can be answered partially. Cost components for wind turbines which are distinct from commercial scale wind turbine as outlined above. The cost includes wind resource assessment, site analysis expenses, the freight of the turbine and its price, as well as tower, construction expenses, interconnection studies, utility system upgrades, protection, transformers, as well as metering equipment, operations, warranty, maintenance, repair, insurance, legal and consultation fees, etc.

Other factors which have an impact on your project economics are financing costs, the size of the project and applicability of taxes.

How much does a wind turbine cost can be answered as under:

The cost of the commercial wind turbines varied from $1 to $2 million per MW of nameplate capacity installed. The same turbines 2 MW in size cost roughly $2.8 million installed capacity. These turbines undergo significant economies scale. Smaller farm or residential scale turbines cost less but they are more expensive when per kilowatt of energy producing capacity is applied on the rates.

This would indicate a 10 kilowatt machine might cost roughly around $48,000. In this manner 100 kilowatts wind turbines would cost roughly $2,800 to $4,800 per kilowatt of capacity. To conclude, how much does a wind turbine cost can be summarized by proper negotiation, considering engineering and other related factors and reducing over all cost incidence on the production process.

Many people save money on electricity by using wind power. Power your house with wind energy and build your own wind turbine with less than 200$. Best guide reviewed.

Best guide to start using wind power as energy and make your own wind powered turbine.

How do residential wind turbines work?

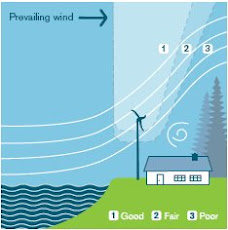

A wind turbine, which is installed on top of a tall tower, collects kinetic energy from the wind and converts it to electricity that is compatible with a home's electrical system.

In a normal residential application, a home is served simultaneously by the wind turbine and a local utility. If the wind speeds are below cut-in speed (7-10 mph) there will be no output from the turbine and all of the needed power is purchased from the utility. As wind speeds increase, turbine output increases and the amount of power purchased from the utility is proportionately decreased. When the turbine produces more power than the house needs, the extra electricity is sold to the utility. All of this is done automatically. There are no batteries in a modern residential wind system.

Small wind systems for remote applications operate somewhat differently.

Do wind turbines make noise or interfere with TV reception?

Small wind turbines do make some noise, but not enough to be found objectionable by most people. A typical residential wind system makes less noise than the average washing machine. Wind turbines do not interfere with TV reception.

Will my utility allow me to hook up a wind generator?

Federal regulations (specifically, the Public Utility Regulatory Policies Act of 1978, or PURPA) require utilities to connect with and purchase power from small (less than 80 MW) wind energy systems. A wind turbine manufacturer should be able to help arrange the required utility company approvals.

Will I have to change any of the wiring in my house?

No. A wind turbine is easily retrofitted to virtually any home without the need to change any wiring or appliances. In most cases, the utility will install a second utility meter to measure how much surplus electricity it is purchasing from the turbine owner.

What about towers?

An 80- to 120-foot tower is usually supplied along with the wind turbine. Towers this tall are necessary to raise the wind turbine above turbulence generated by obstacles on the ground and trees. Wind velocity and, therefore wind turbine performance, increases with altitude. Several different types of towers are available, depending upon which manufacturer you select. Each type has its advantages; the most economical type of tower is the guyed lattice tower, but a hinged tower can be easier for you to install yourself and provides easier access for maintenance.

How much does a wind system cost?

A small turbine can cost anywhere from $6,000 to $22,000 installed, depending upon size, application and service agreements with the manufacturer.

How reliable are wind turbines? Will I have to perform much maintenance?

Most small turbines have very few moving parts and do not require any regular maintenance. They are designed for a long life (up to 20 years) and operate completely automatically.

How do wind turbines perform as an investment?

The wind system will usually recoup its investment through utility savings within six to 15 years and after that the electricity it produces will be virtually free. Over the long term, a wind turbine is a good investment because a well-sited wind system increases property value, similar to any other home improvement. Many people buy wind systems in preparation for their retirement because they don't want to be subject to unpredictable increases in utility rates.

How would I have a wind turbine installed at my home?

Most dealers offer either complete turnkey (ready-to-operate) installations or the option to purchase direct from the factory and install the system yourself. The first option offers more customer support from the company. Self-installation offers significant savings and a hands-on understanding of the turbine. Prospective owners can discuss the options available with manufacturers to decide which method best suits their budget and technical skills.

Yietta Chrysostomou (9O)

Simphiwe Tsela (9O)

Amilcar Thobejane (9N)

Angelica Marques (9C)

Anuska Lakha (9A)

Sarah Dold (9N)

Giverny Ganz (9N)

Marc Relou (9R)

Amy Nickelson (9W)

Michael Boltman (9C)

Joshua Yeatman (9W)

Tyler Sanster (9W)

Michael Purnell (9N)

Blake Stead (9N)

Kirsten Trankle (9N)

skip to main |

skip to sidebar

CAN CORNWALL GO GREEN? THIS IS THE OFFICIAL SITE FOR THE COMBINED GRADE 9 FEASIBILITY STUDY TO DETERMINE IF A WIND DRIVEN TURBINE CAN REDUCE THE CHC ELECTRICAL BILL AND CARBON FOOTPRINT.

No comments:

Post a Comment