1) Andrew Walters (90)

Horisontal WT

- Small WT's have wind vanes that turns the blade towards the wind.

- Large WT's has a gearbox that turns the blade towards the wind.

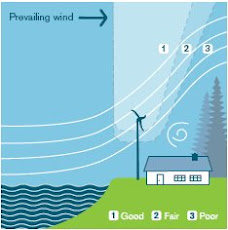

- Every 10m of height increases the wind by app. 20% and output capacity by 34%

- Hard to transport

- Difficult to install and maintain.

- Can interfere with cellular towers.

Vertical WT

- Do not need to pointed into the wind.

- Good for places where wind direction changes a lot.

- Easier to maintain because of access to gearbox and blades proximity to the ground.

- Smaller and lighter (Can be placed on buildings)

- Can start producing power at 10km/h

- Less efficient in high winds compared to horisontal WT's

2) Phillip Rust (90)

Some WT could have blades that are 35m or longer and stand as high as 65m.

Required wind speed for a tower WT is app. 25mph.

Operational sweeping footprint of a 1.5megawatt WT's blade is app. 3 square kilometres.

Volkswind (Germany):150watt capacity

Westas and General Electric (American):1.5 - 3 megawatt capacity, total height app. 100m

3) Alexander Ham (9A)

Early windmills in Holland just had flat blades compared to the modern aerofoil that creats lift which pulls the blade along.

In "lift" one of the blade is flat and the opposite side is curved. when the wind moves over the curved area it speeds up and creates a low pressure pocket above the blade. The low pressure area "pulls" the blade towards it.

The is a limit the speed that a WT blade can travel called the "Betz limit" ( Named after the person who discovered and formulated the eqasion) Blades create a high pressure area in front whilst rotating which forces some air out and around the WT.

4) Marjolein Naudé (9A)

Wind turbines are designed to exploit the wind energy that exists at a location. Aerodynamic modeling is used to determine the optimum tower height, control systems, number of blades {factApril 2009} and blade shape. Wind turbines convert wind energy to electricity for distribution.

Conventional horizontal axis turbines can be divided into three components.

The rotor component, which is approximately 20% of the wind turbine cost, includes the blades for converting wind energy to low speed rotational energy.

The generator component, which is approximately 34% of the wind turbine cost, includes the electrical generator, the control electronics, and most likely a gearbox component for converting the low speed incoming rotation to high speed rotation suitable for generating electricity.

The structural support component, which is approximately 15% of the wind turbine cost, includes the tower and rotor yaw mechanism."

5) Nicholas Herbst (9C)

This is an example of WT specifications supplied by a company called African Windpower. www.africanwindpower.com

These should help give guidelines to many aspects of the project. Keeping in mind this is a very small WT so a multiple of these might be needed in order to cover the CHC electrical bill.

AWP 3.7 Specifications

Peak Power Rating

1500 W at 48V - 2000 W in 110/220V Inverter Grid Connect System

Energy Production

(Predicted) 4m/s 8KWHrs/Day, 5m/s 12KWHrs/Day,6m/s 20KWHrs/Day

Rated Wind Speed

12m/s

Start up wind Speed

3.5m/sec

Cut in Wind Speed

3m/sec

Alternator Design

30 Pole (Ceramic Magnet) Rotor, Laminated Axial Stator

Electrical Output

3 Phase 'Wild' AC, 0-100Hz, 12V,24V,36V,48V,96V,110/220V

Rotor Diameter

3.7 Meters

Maximum RPM

500

Number of Blades

3

Blade Construction

GRP Composite design

Speed/Power Control

Side Furling Gravity Return Yaw System

Max Design Windspeed

60m/sec

Configuration

Upwind Rotor - furling tail

Corrosion protection

Powder coated (White)

Marine protection

Hot dip galvanised

Cable Connection

Heavy duty slip rings

Tower Top Mounting

3 Inch (80mm NB) Table D Flange - (4 x 18mm Bolts 150mm PCD)

Tower Top Weight

120Kgs (220 Pounds)

Battery Charge Control

Turbine Side ,high side diversion dump control

Dump Load

Wall mounted resistive heater 1500W

Shipping dimensions

160Kg (308 Pound) Crate 1900x 570x 540mm (74x23x21ins)

6) Stas Osuch '9C'

Specifications for an 80 k/w wind turbine:

Ideal use for:

• Schools/office buildings

• Poultry/cattle/dairy farms

• Resort hotels

• Golf courses

• Agricultural businesses

• Manufacturing plants

• Remote villages - island power systems

The noise produced is 95 decibels at a speed of 10 m\s. This at the source, right next to the turbine. 100m away from the turbine there are 45 decibels produced. That means that about 200 meters away from the turbine it will not be heard. It has Sound reduced gearbox, rotor blades with minimized noise level.

Dimensions:

Rotor – 18m diameter carbon fiber (9 meter each blade).

Tower - 18-40m. made out of steel: tubular or lattice.

Foundation – Concrete block with anchors.

‘a-synchronous generator.’ Produces 160,000 kWhrs yearly.

Weight 13 000 kg.

Safety features:

Electro mechanical pitch control for each blade.

Hydrolic parking brake.

Cost: $120,000 (R 965,387.993)

The lightning protection system :

Lightning receptors installed on blade tips.

Surge protection in electrical components.

This comes pre-engineered.

Liam O Niel (90)

Tim Marshall (9C)

Andrew Van Zyl (9W)

Connor Davison (9O)

Blaine Witten (9N)

Lauren Teichert (9N)

Kgomotso Mogashoa (9O)

Erryn Moodley (9N)

Roger dos Santos (9R)

Riccardo Rincon (9R)

Bradley Cohoe (9W)

Nicholas Leighten (9O)

Victor Wymeersch (9C)

Ryan Phillips (9W)

Damian Lewis (9C)

Aidan Taylor (9A)

Karl Frenzel (9W)

Gregory Avieros (9W)

Dylan Hull (9R)

Ruben Pretorius (9W)

Kaylan Naicker (9C)

skip to main |

skip to sidebar

CAN CORNWALL GO GREEN? THIS IS THE OFFICIAL SITE FOR THE COMBINED GRADE 9 FEASIBILITY STUDY TO DETERMINE IF A WIND DRIVEN TURBINE CAN REDUCE THE CHC ELECTRICAL BILL AND CARBON FOOTPRINT.

No comments:

Post a Comment