1) Jane' Storm in (9R)

Extreme Loads -Forces:

Wind turbines are built to catch the wind's kinetic (motion) energy.

Turbines with many blades or very wide blades, will be subject to very large forces, when the wind blows at a hurricane speed.

Wind turbine manufacturers have to certify that their turbines are built, so that they can withstand extreme winds which occur, say, during 10 minutes once every 50 years.

To limit the influence of the extreme winds turbine manufacturers therefore generally prefer to build turbines with a few, long, narrow blades.

In order to make up for the narrowness of the blades facing the wind, turbine manufacturers prefer to let the turbines rotate relatively quickly.

Fatigue Loads -Forces:

This is particularly the case if they are located in a very turbulent wind climate.

Components which are subject to repeated bending, such as rotor blades, may eventually develop cracks which ultimately may make the component break. Metal fatigue is a well known problem in many industries. Metal is therefore generally not favoured as a material for rotor blades.

When designing a wind turbine it is extremely important to calculate in advance how the different components will vibrate, both individually, and jointly. It is also important to calculate the forces involved in each bending or stretching of a component.

This is the subject of structural dynamics, where physicists have developed mathematical computer models that analyse the behaviour of an entire wind turbine.

These models are used by wind turbine manufacturers to design their machines safely.

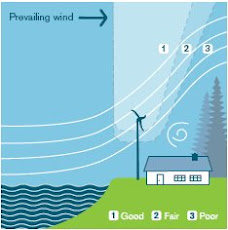

Upwind Machines:

Upwind machines have the rotor facing the wind. The basic advantage of upwind designs is that one avoids the wind shade behind the tower. By far the vast majority of wind turbines have this design.

The basic drawback of upwind designs is that the rotor needs to be made rather inflexible, and placed at some distance from the tower (as some manufacturers have found out to their cost). In addition an upwind machine needs a yaw mechanism to keep the rotor facing the wind.

Downwind Machines:

Downwind machines have the rotor placed on the lee side of the tower. They have the theoretical advantage that they may be built without a yaw mechanism, if the rotor and nacelle have a suitable design that makes the nacelle follow the wind passively. For large wind turbines this is a somewhat doubtful advantage, however, since you do need cables to lead the current away from the generator. How do you untwist the cables, when the machine has been yawing passively in the same direction for a long period of time, if you do not have a yaw mechanism? (Slip rings or mechanical collectors are not a very good idea if you are working with 1000 ampere currents).

A more important advantage is that the rotor may be made more flexible. This is an advantage both in regard to weight, and the structural dynamics of the machine. The basic advantage of the downwind machine is thus, that it may be built somewhat lighter than an upwind machine.

The basic drawback is the fluctuation in the wind power due to the rotor passing through the wind shade of the tower. This may give more fatigue loads on the turbine than with an upwind design.

Megan Hesse (9N)

Patricia edwards (9N)

Naudette McDuling (9R)

Danielle Botha (9A)

Saba Ashoori (9N)

Darryl - Lynne Borcher (9C)

Krisna Els (9A)

Gabby Farmer (9A)

Nkateko Phakula (9R)

Lisa Jeneker (9N)

Erashin Moodley (9W)

Carmen Fourie (9R)

Emica Swart (9W)

Claire Jordaan (9W)

Daleen Conradie (9R)

John Atfield (9N)

Rhys Rae (9A)

skip to main |

skip to sidebar

CAN CORNWALL GO GREEN? THIS IS THE OFFICIAL SITE FOR THE COMBINED GRADE 9 FEASIBILITY STUDY TO DETERMINE IF A WIND DRIVEN TURBINE CAN REDUCE THE CHC ELECTRICAL BILL AND CARBON FOOTPRINT.

No comments:

Post a Comment